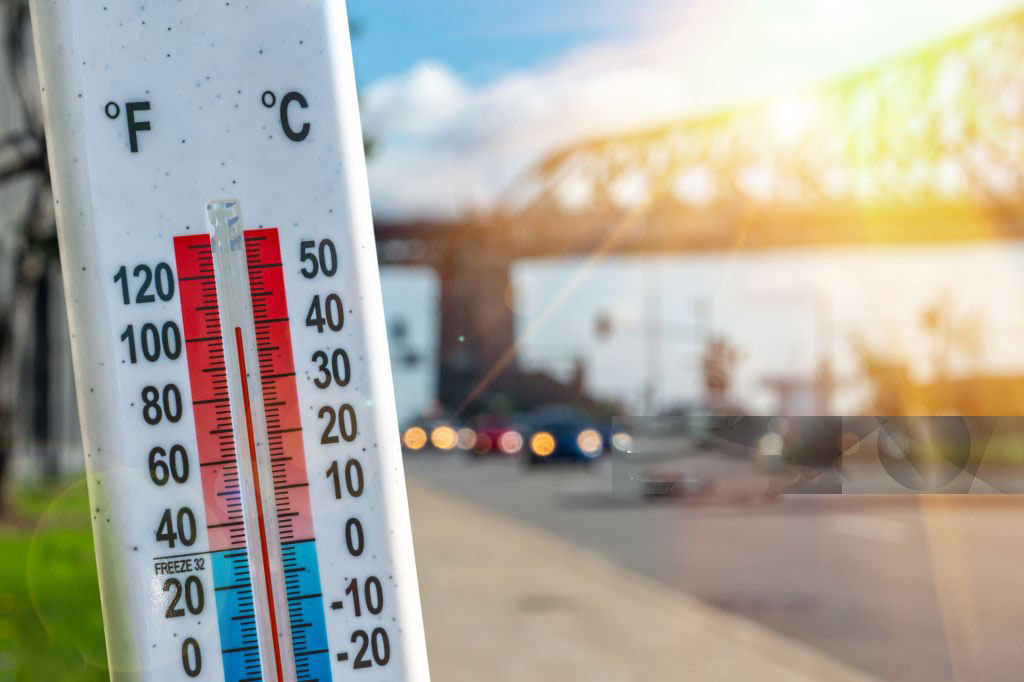

When the Heat is On!

When the Heat is On: How Hot Weather Affects Lubricants

Lubricants play a crucial role in keeping things running smoothly, from the engine in your car to the bearings in your dishwasher. But just like the rest of us, lubricants struggle when the temperatures start to climb. Here’s what you need to know about the effects of hot weather on your lubricants:

Viscosity Blues: Imagine honey on a cold day versus a hot day. That’s what happens to lubricants with temperature. As it gets hotter, the lubricant thins out, losing its ability to form a protective film between moving parts. This leads to increased friction, wear, and tear.

Breakdown Boogie: High temperatures accelerate the breakdown of the base oil and additives in lubricants. This not only reduces their viscosity, but also diminishes their anti-wear, anti-oxidation, and anti-corrosion properties, leaving your machinery unprotected.

Volatility Tango: Some lubricant additives are like mini perfumes – they have a tendency to evaporate at high temperatures. This loss depletes their protective properties and can even leave deposits on sensitive surfaces.

Grease Gone Wild: High temperatures can cause the oil and thickener in greases to separate, rendering them less effective. This is especially problematic for sealed bearings that rely on grease for long-term lubrication.

The Domino Effect: Hot lubricants don’t just suffer themselves, they can wreak havoc on other components too. Increased friction means more heat, creating a vicious cycle that can damage seals, filters, and even cause catastrophic failures.

So, what can you do?

- Use the right lubricant: Different applications require different lubricants formulated for specific temperature ranges. Consult your manual or a lubrication specialist for the right choice.

- Monitor temperatures: Keep an eye on operating temperatures and reduce loads or shutdown equipment if things get too hot.

- Change lubricants more often: Hot weather shortens lubricant life, so be sure to change them more frequently. Follow the manufacturer’s recommendations for your specific application.

- Upgrade your cooling: Consider additional cooling systems for machinery operating in hot environments.

By understanding the effects of hot weather on lubricants, you can take steps to protect your equipment and keep it running smoothly even when the mercury rises. Remember, an ounce of prevention is worth a pound of (melted) metal!